UL-recognized options are available for continuous service up to 200 °C (392 °F), depending on construction.

Note: For non-stick release and continuous service up to 260 °C (500 °F), see our PTFE-coated fiberglass tapes (Temperature Tape).

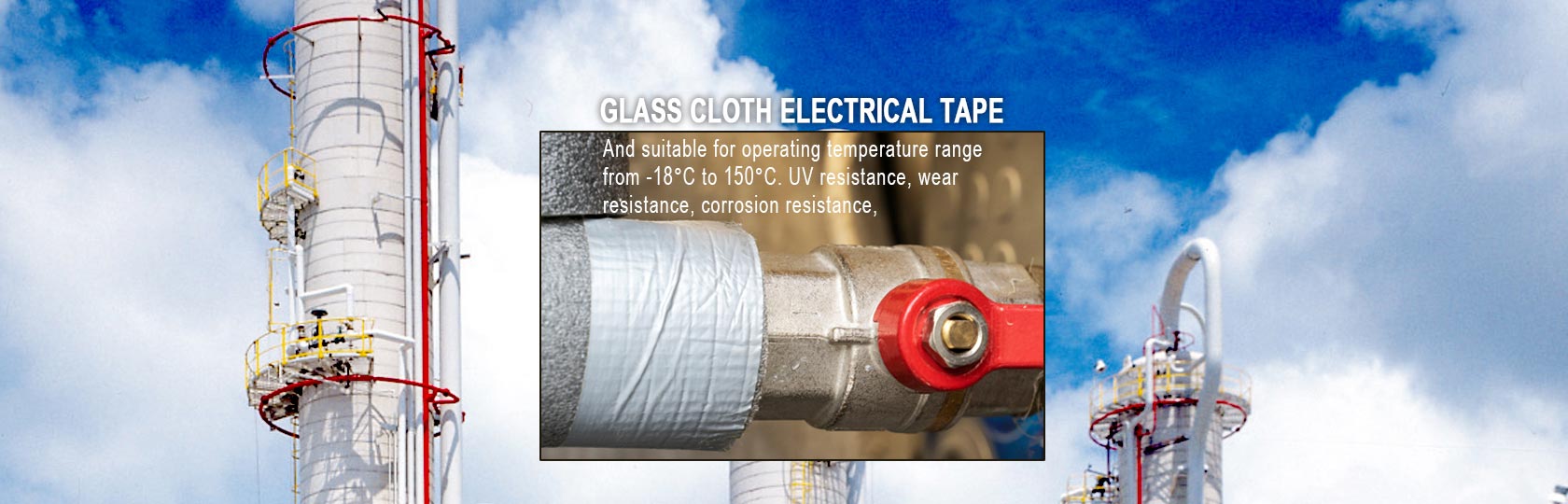

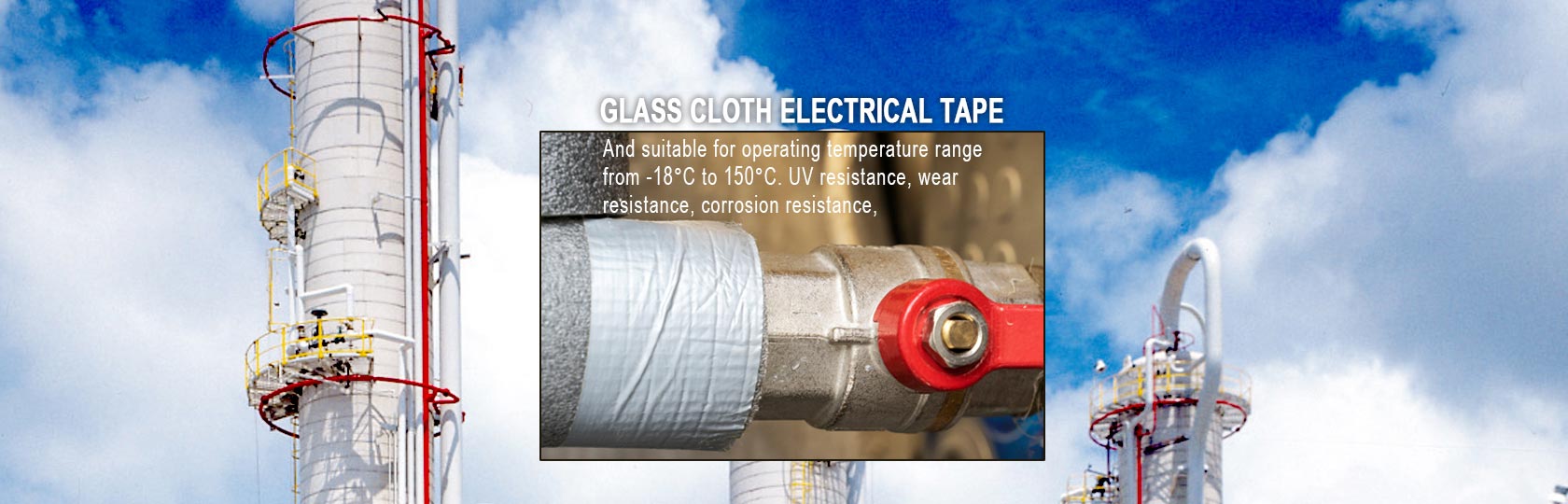

A flame-retardant fiberglass cloth backing paired with a high-temperature silicone adhesive for long-lasting electrical insulation.

It delivers high tensile strength, abrasion and solvent resistance, and conforms without edge-tear — ideal for coil/transformer outer wrap, motor leads, and cable bundling in hot zones.

Coil cover, anchor/banding, layer and crossover insulation for transformers; motor and generator leads; furnace/oven control wiring; cable/harness bundling in engines and industrial equipment; high-heat splicing, holding, and masking where abrasion and solvents are present.

A woven fiberglass backing with a thermosetting silicone adhesive maintains adhesion at elevated temperatures while providing mechanical strength for durable 600-V dry-location insulation. Designed for varnish impregnation processes and high-heat assemblies that demand long-term stability.

▲Fiberglass tape is used to twine the pipe, which can strengthen the temperature resistance of the pipe to 150–250 °C (302–482 °F).

About PVC Electrical Tape: General-purpose PVC electrical tapes use a plasticized PVC backing and non-corrosive rubber-based adhesive. They stretch to conform for everyday splicing and insulation.

For high heat, abrasion, and solvent exposure, step up to glass cloth electrical tape with silicone adhesive, typically rated 150–200 °C (302–392 °F) for continuous service.

In-house woven fiberglass cloth with consistent weave, high tensile strength, and dimensional stability. Custom widths (50–3400 mm), finishing, and OEM slitting available to match tape converters’ needs—supported by NAN YA’s vertically integrated supply and global network.